Lumitex® Fiber Optic Panels

Lumitex is a certified ISO 9001 and ISO 13485 manufacturer.

Lumitex® Fiber Optic Panels transmit light from light sources to stranded fiber optic panels. The technology can be integrated with LED’s and electronic circuitry to backlight electronics, transportation and medical applications. Lumitex offers two different stranded fiber optic choices: Woven Fiber Optics™ and Uniglo®.

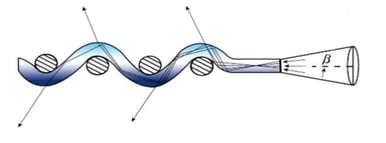

Woven Fiber Optics™

Lumitex Woven Fiber Optic™ Panels utilize a proprietary computer-controlled process to produce precisely engineered micro bends in the optical fiber to uniformly extract the light throughout the panel length. The cladded fiber enables the integration of back reflectors, brightness enhancing films, and adhesives to achieve the optical specification for the application.

Benefits of Woven:

- Most robust of Lumitex technologies

- More efficient brightness per layer

Uniglo®

Lumitex Uniglo® Panels utilize a proprietary abrasion process to extract light and provide uniform illumination across an entire panel. The light extraction process allows for selective patterns to illuminate specific areas or shapes. Because of its extremely thin profile Uniglo provides excellent tactile feel in switch applications

Benefits of Uniglo:

- Thinnest and most flexible Lumitex Fiber Optic panel

- Bendiglo™ (a derivative of Uniglo) allows bends in the panel up to a full circular profile

Features of Woven and UniGlo Panels

- Uniform lighting developed through proprietary processes

- Efficient design allows for prototypes to be built quickly, with minimal NRE

- Thin, flexible, low profile that enables the ability to backlight complex designs

- Design flexibility through color, sizing, forming, and layering

- Ability to do varying levels of design complexity. Lumitex can provide flexibility and expertise where needed

- Light source is remote from the light panel

- Carefully selected light sources provide required color, uniformity, and output

Applications

- Membrane Switches/Keypads

- Badges

- Accent Lighting

- Automotive Lighting Interior/Exterior

- LCD’s

- Military

- Recreational

- Surgical Retractor Lighting

- Phototherapy application

Construction of Woven and Uniglo Panels

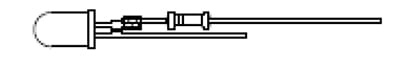

- Standard Sources:

- A variety of 3mm and 5mm bullet nose sources are available with standard coupling in Green, White, Blue, and Red.

- A variety of 3mm and 5mm bullet nose sources are available with standard coupling in Green, White, Blue, and Red.

- Standard Materials:

- The standard offering of materials to help meet application requirements includes Melinex polyester films, diffusers, laminates, adhesives, braided sleeves, and tubing.

- Layers:

- Multiple layers of Woven or Uniglo Fiber Optic Panels can be used to enhance brightness while maintaining uniformity.

- Design Complexity:

- Low: Light Guide only. Customer supplies their own sources and electronics.

- Moderate: Light Guide and Source. Customer only needs to supply power.

- High: Light Guide, Source, Electronics. Lumitex provides full integration into customer's design.

Technical Specifications for Woven and Uniglo Panels

- Core material: PMMA

- Cladding: PVDF

- Minimum Thickness Uniglo: 0.33mm (one layer only)

- Minimum Thickness Woven: 0.84mm including back reflector (one layer only)

- Core index of refraction: 1.4906

- Numeric Aperature: .45

- Operating Temperature: -40°C to 70°C

- Vicat Softening Tempurature: 80°C

- Standard for Uniformity: +/-30% uniformity for up to an 8”input (Uniformity as a function of the average Output)

- Lumitex can work with any voltage requirements and will design around the source provided

The data and details in this document were correct and up-to-date at the time of printing and are intended to provide information on our products and their possible applications. It is the user’s responsibility to obtain the latest version of the product data sheet. This data sheet is not a specification and does not assure specific product characteristics or make reference to the suitability of the product for a specific application. Because Lumitex cannot anticipate or control every application, we strongly recommend testing of this product under individual application conditions. The application, use and conversion of this product are the user’s responsibility

LUMITEX DISCLAIMS ANY AND ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

NOTE: Lumitex does not assume any responsibility or liability for any advice furnished by it, or for the performance or results of any installation or use of the product(s) or of any final product into which the product(s) may be incorporated by the purchaser and/or user. The purchaser and/or user should perform its own tests to determine the suitability and fitness of the product(s) for the particular purpose desired in any given situation.