Engineering design is the process (often through iteration) that engineers use to create products, devise a system or process to meet the desired need. It involves an organized series of steps establishing objectives, analysis, and evaluation. The steps contribute to a successful desired outcome.

As a world-class lighting technology integrator, we provide the right lighting technology for your application at the right time. Good engineering design practices start with careful consideration of the product requirements up front to reduce the delays and redesign costs later. In this article, we discuss the engineering design process, from design input to a successful design output, and best practices.

Manage Your Project Through Design Process

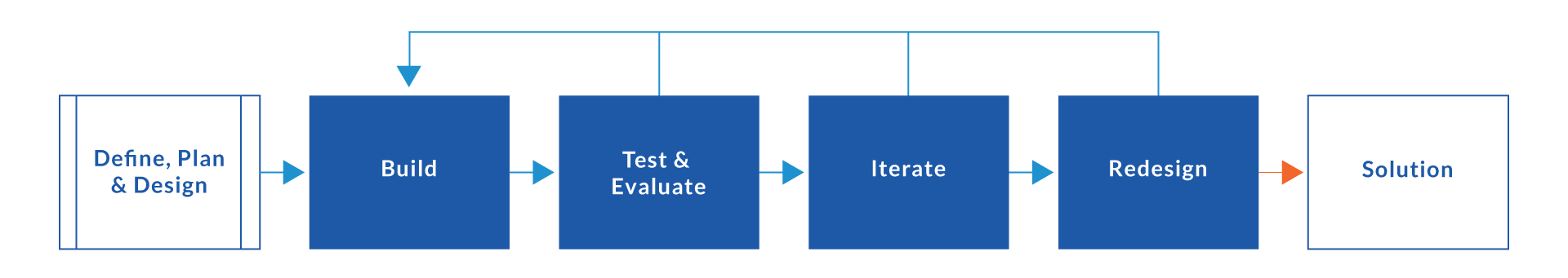

The engineering design process is the steps one goes through to solve a problem and provide a solution. In other words, it starts with a problem and ends with a solution.

The steps can vary depending on your project but for the most part includes:

1. Define/Clarify exactly what the problem is. What are the challenges? limits?

2. Plan a solution with idea creation. Explore your options.

3. Design by choosing the most promising solution.

4. Build a prototype.

5. Test and evaluate.

6. Iterate. After your idea is implemented include gathering feedback and constant improvement.

7. Redesign. Measure it. Test it again. Did the changes make a difference? Based on feedback, the same cycle would repeat until the desired outcome or best solution was achieved.

It is a process that can be applied to any problem.

Engineering Design Practices - Integrating People, Process and Technology

"Any practice whether a technique, a method, a process, or an activity that enables to deliver more efficiency and/or effectiveness than any other manner can be considered as a best practice." [source: Barczak G, Kahn KB. Identifying new product development best practice. Business Horizons, 55(3), 293–305, 2012].

Good engineering practices, (GEP) are in place to ensure that the "development and/or manufacturing effort consistently generates deliverables that support the requirements for qualification or validation."

Engineering design practices begin with a strong collaborative development process and the defined roles of your team. Only then can a support process be put to task with key criteria and objectives.

The upfront design is a crucial component of the process. It is estimated that 70 percent or more of the life cycle cost of a product is determined during design. Effective design and best practices will improve quality and reduce costs.

According to the National Academies of Sciences, Engineering, and Medicine (NASEM), a study of companies that used design most effectively were found to:

- commit to the iteration process (continuous improvement)

- follow a product realization process (PRP) (have a clear idea of what the product will be from initial planning to customer follow-up)

- use a set of design practices they chose to implement their product realization process (the process includes determining needs, engineering specifications, design, and production)

- promote a complementary design environment

source: National Academy of Sciences, "Improving Engineering Design: Designing for Competitive Advantage, at NAP.edu

Real-World Example From a Lighting Technology Integrator

Below is an example of how electronics backlight could integrate before the design begins.

When choosing your backlighting technology, you need to acknowledge

- brightness

- space

- cost requirements

- uniformity of the light desired

Engaging the right technical resources early in the design can significantly improve the design, lower cost and accelerate development.

Epec, a global manufacturer of custom engineered components, agrees saying...

"Successful OEM designers or industrial designers should work early in the design concept phase to keep from being painted into a corner."

Paul Knupke, Epec Engineered Technologies, used the analogy - where "backlighting is integral to the design, not an option feature, like choosing between leather or cloth seats in a new automobile. "Backlighting decisions are similar to deciding a new automobile must seat 7 passengers before considering a sub-compact automobile." [source]

Butler Technologies found when industrial designers and engineers put the backlight design further in the project's timeline, they literally back themselves into a dark corner...

"Without considering where LEDs, light guides and the circuits fall into the overall look, you can literally design yourself into a dark corner."

A good design process upfront yields a successful output.

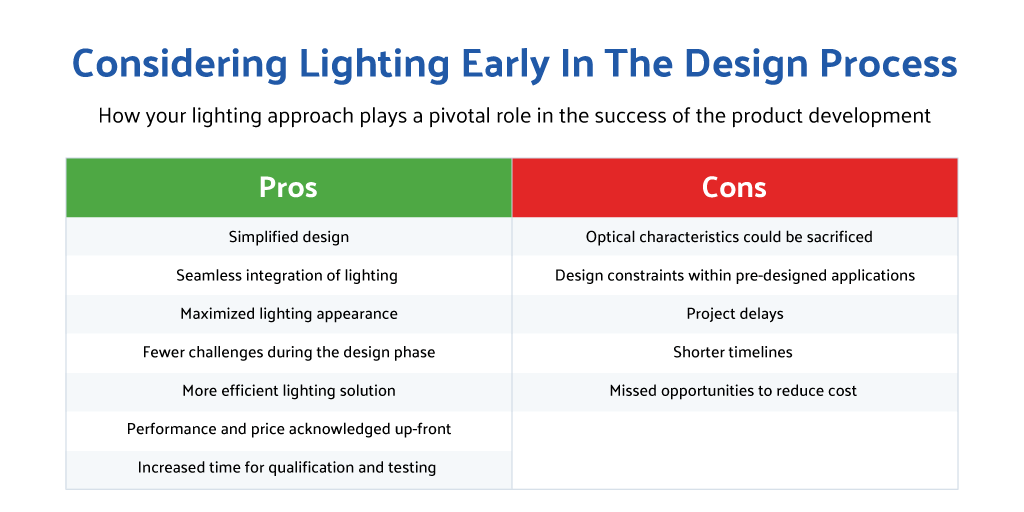

Lighting Technology Should Not Be An Afterthought in Design

If you are considering utilizing lighting in your application, your lighting approach could bring advantages and disadvantages to your overall product development.

We highlighted below a few of the pros and cons you need to think about when considering light.

Understanding your lighting approach early on will make the process less difficult. Lighting solutions to enhance performance (as part of the design process) should be addressed early in the design concept phase.

Conclusion

Engineering involves a creative approach and practical evidence for the design, finish, and final product.

A great lighting solution enhances the product from function to perception.

Comments