More than just light guides

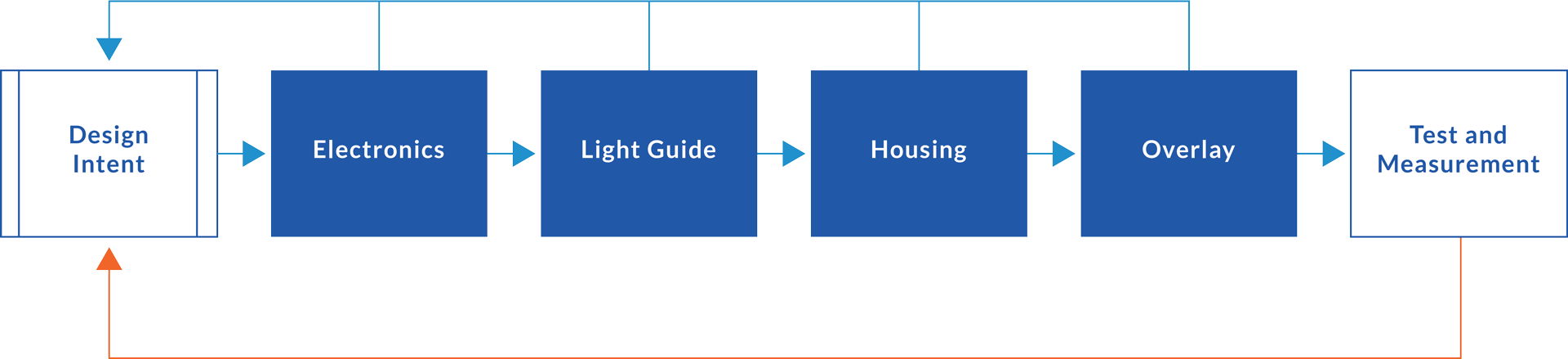

We have the capability to mill copper laminates, providing a prototype circuit board. We can populate common surface mount and through-hole components, leading to a representative sample of your electronics.

Our lighting can be rapidly prototyped without large tooling fees or long lead times associated with molded options. We can also rapidly iterate through optical patterning to fine tune performance. This ensures your customer demonstration or show piece will look its best with minimal lead time.

Utilizing both additive and subtractive tools like FDM 3D printing and CNC machining, we can create housings and enclosures. This puts a working model in your hands to evaluate fit, form, and limited function.

We offer a selection of materials that can provide diffusion, brightness enhancement, and cutout apertures to demonstrate lettering and icons. This give an impression of how the final product might look.

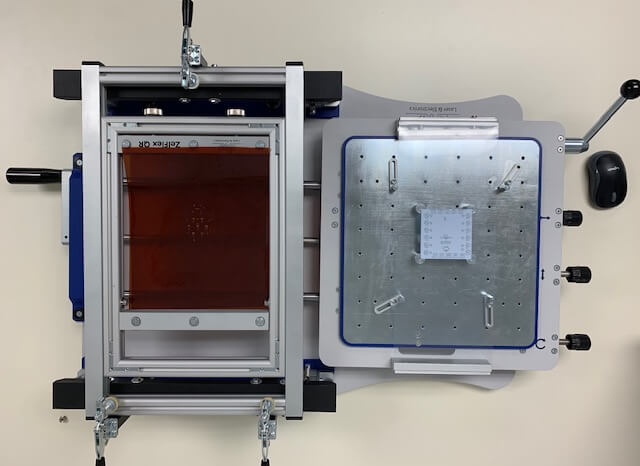

Our goal is to provide you with a prototype that will enhance your overall application and that can get into your customers’ hands quickly. We utilize many different types of equipment to get you a production representative part that will delight your customers. See some of the equipment we use in the lab below.

Get latest illumination tips, updates and ideas delivered to your inbox!