What is Rapid Prototyping?

Rapid prototyping is the group of techniques/technologies available to engineers to create a three-dimensional scale model of a physical part or assemble them using 3D CAD data.

RP is greatly broadening the manufacturing industry with its easy transformation of assembling a physical object from a digital model to test for form, fit and function. In its simplest terms, it is the process of creating prototypes to evaluate an engineering product design.

As illumination experts, we are dedicated to stay on top of the competitive landscape manufacturers are faced with today. In a world that is constantly seeking faster time to market, manufacturers need to expedite their time-frame and schedules in the product development cycle. RP prototype or Rapid prototyping offers companies the opportunity to remain competitive by introducing new products faster.

In this article, we discuss the benefits of rapid prototyping, compare technologies, and review different prototyping stages and factors that should be considered.

How Does Rapid Prototyping Work?

The process begins with a digital model created through computer-aided design (CAD) software. Once the design is finalized, it's converted into a format that can be interpreted by prototyping machines, most commonly STL files. These files guide the equipment to produce the prototype layer by layer, depending on the selected technique.

The terms "prototyping," "rapid prototyping," "3D printing," and "additive manufacturing" are often used interchangeably. However, they each refer to distinct aspects of the production process.

Prototypes: Indispensable Part of Engineering Product Design

Prototypes are vital especially when it comes to the new product development process. They help eliminate risk and bring a product idea to life. There are many terms tossed around the industry when we think of prototyping.

The terms "prototyping", "rapid prototyping", "3D printing", and/or "additive manufacturing" are commonly used side-by-side. They are used interchangeably, but in fact have different meanings.

Difference Between 3D Printing and Rapid Prototyping

"Rapid prototyping is the technique of fabricating a prototype model from a CAD file. 3D printing/additive manufacturing is the process, and rapid prototyping is the end result. Rapid prototyping is one of many applications under the 3D printing/additive manufacturing umbrella." [Source]

Rapid Prototyping is an application used in additive manufacturing to create a model faster than what would be considered the normal process. Engineering Product Design states,

"3D printing on its own or in combination with other processes could be used to create rapid prototyping."

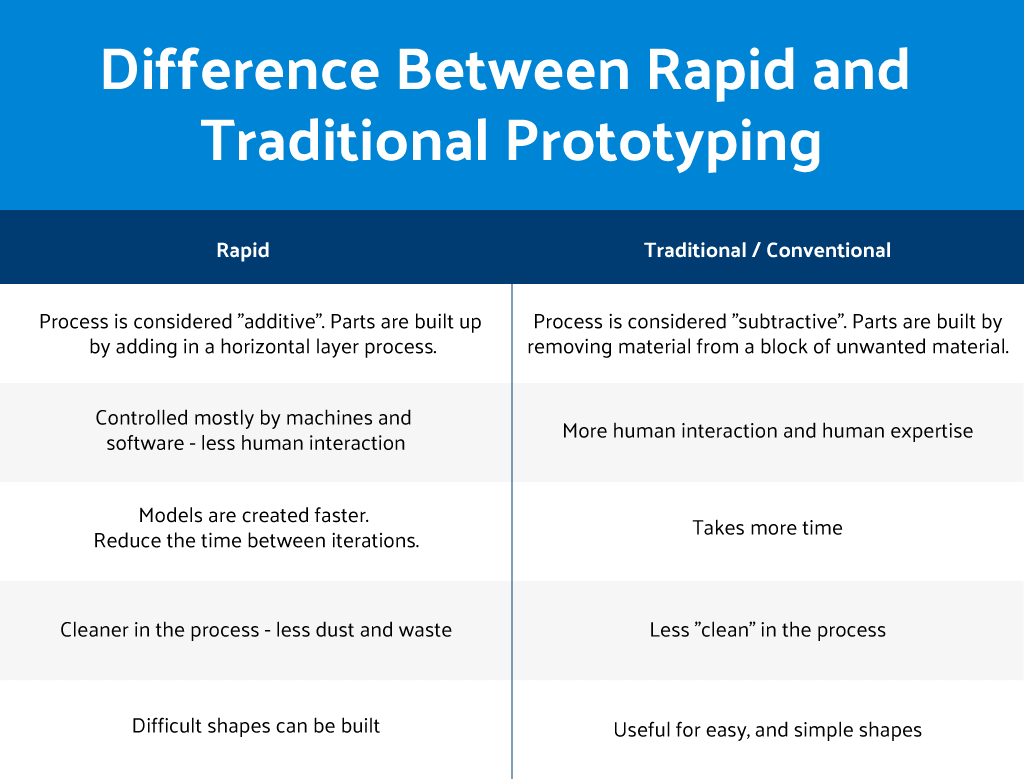

Let's look at the difference between traditional prototyping and rapid prototyping. Both are advanced processing methods for prototypes.

However...

They use a completely different process.

Selecting a Rapid Prototyping Process

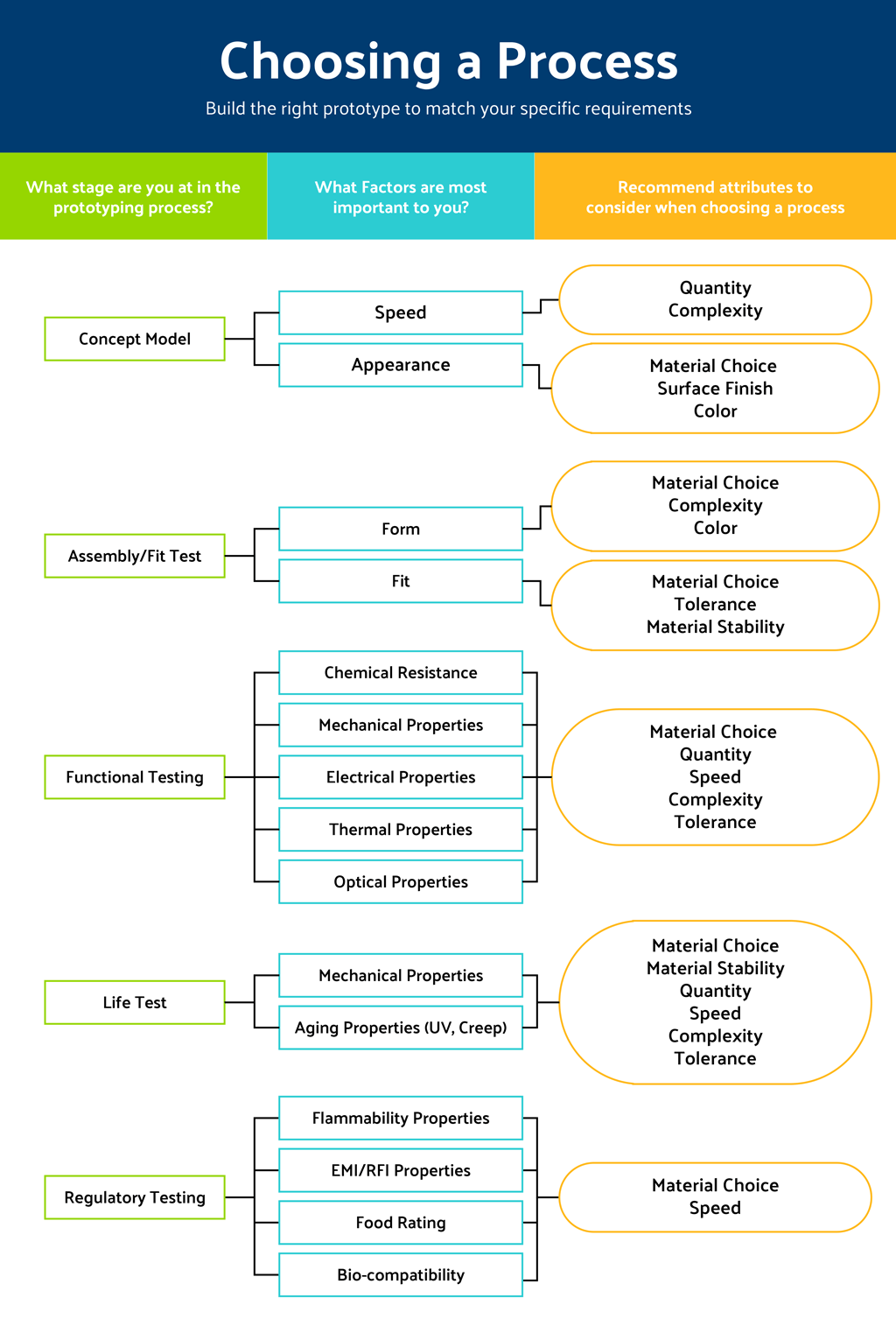

In order to build the right prototype to match your specific requirements, you need to decide which factors are the most critical based on your situation.

source: Selecting a Rapid Prototyping Process | White Paper https://www.protolabs.com/resources/white-papers/rapid-prototyping-processes/

Methods/Technology Available for Different Applications

Stereolithography (SLA) - technology that converts liquid materials, layer by layer, into solid parts by curing them using a light source process.

Laser Sintering - additive manufacturing (AM) technology that utilizes lasers to sinter powdered plastic material (typically nylon/polyamide) into a solid structure based on a 3D model.

Direct Metal Laser Sintering (DMLS) - is a direct metal laser melting technology that forms accurate and complex geometries not possible with other metal manufacturing methods.

Fused Deposition Modeling - the most widely used method that uses a thermoplastic filament that's heated to its melting point and forced out, layer by layer, to create a 3D object.

Multi Jet Fusion - 3D printing process that produces functional nylon prototypes and end-use production parts as quick as 1 day.

Injection Molding - method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them. Widely used process to create items like plastic trinkets, water bottles, cell phone cases, toys and more.

How Rapid Prototyping Fits into the Engineering Design Process

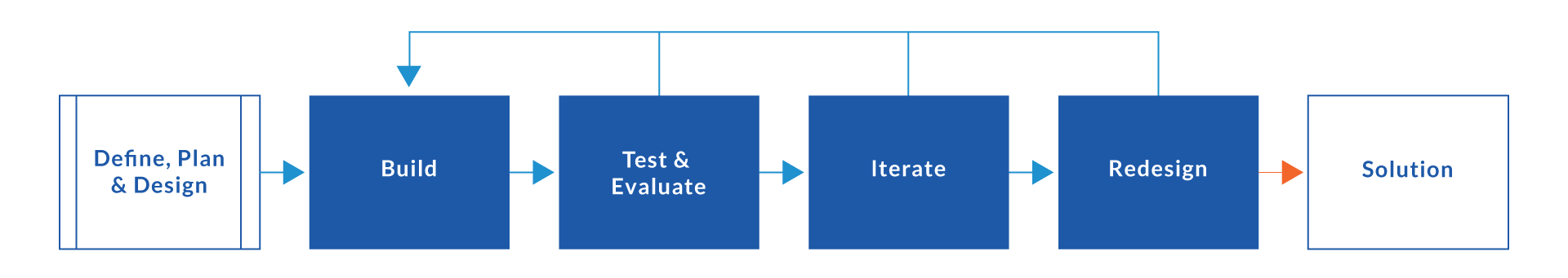

The engineering design process is the steps one goes through to solve a problem and provide a solution. In other words, it starts with a problem and ends with a solution.

The steps can vary depending on your project but for the most part includes:

- Define/Clarify

- Plan

- Design

- Build a prototype

- Test

- Iterate

- Redesign

It is a process that can be applied to any problem. Rapid prototyping fits into step 4 - "Build a prototype".

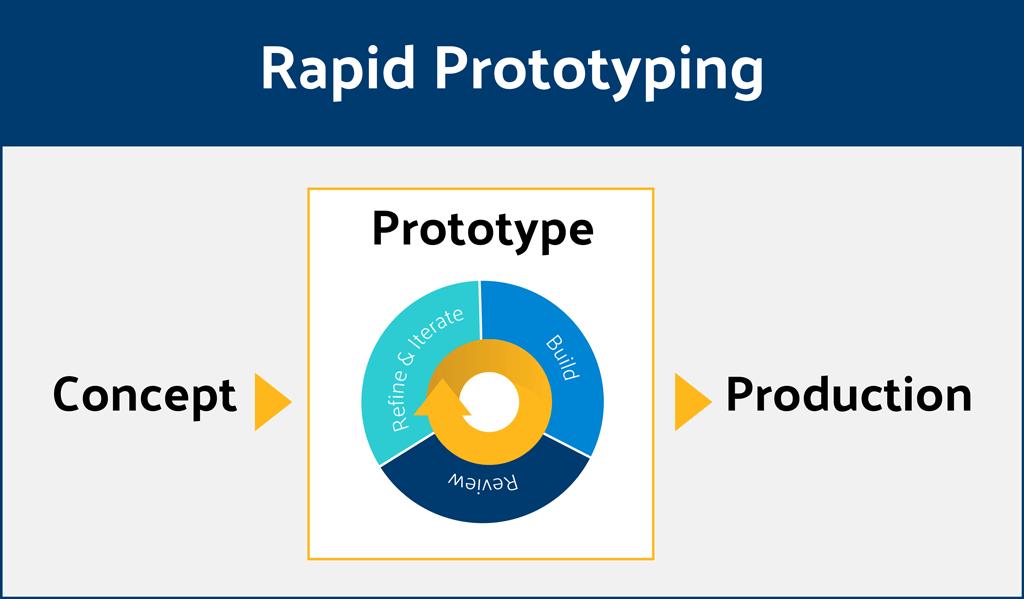

To break it down further, RP would look similar to this image:

source: What is Rapid Prototyping & Its Techniques http://engineeringproductdesign.com/knowledge-base/rapid-prototyping-techniques/

Concept development involves identifying potential risks and setting a plan in action. The process is based on iterations that produce prototypes that will be tested and refined.

The goal is to agree on the look and feel of a design prior to production. The final step will be the manufacturing of the product with quality control processes in place.

Advantages of Rapid Prototyping

Product design failure in the development stage can cause a substantial loss for a company. Rapid prototyping is a cost effective way to develop and test an idea. The advantages of RP can produce a model to test the product for its performance and efficiency.

Here are 7 Benefits for Rapid Prototyping:

Enhanced Visualization of Design Concepts

Rapid prototyping allows designers and stakeholders to see a tangible version of the product early in the development process. This physical or digital model makes it easier to understand the shape, form, and function, allowing for quick feedback and immediate adjustments if needed.

Saves Time and Reduces Costs

Traditional prototyping methods can be slow and expensive. With RP, the turnaround is much faster, reducing the time spent between design iterations. This accelerates the development timeline and cuts down on expenses related to tooling, setup, and labor—resulting in a faster time-to-market.

Greater Design Customization

Rapid prototyping supports quick design iterations, making it easier to tailor the product to specific needs. Whether it's tweaking the shape, switching materials, or adjusting dimensions, RP allows for high flexibility with minimal extra cost or time.

Increased Accuracy and Error Detection

RP tools and technologies provide high precision, which means prototypes closely resemble the final product. This accuracy helps identify design flaws, functionality issues, or structural weaknesses early on—before they become expensive problems during manufacturing.

Minimized Material Waste

Because RP is typically done in a controlled, additive manufacturing process (like 3D printing), there's significantly less material waste compared to traditional subtractive methods. This not only saves money but also supports more sustainable production practices.

Functional and Performance Testing

Prototypes made using RP can often mimic the functionality of the final product. This enables real-world testing for ergonomics, usability, and performance. Designers can confirm whether the product behaves as expected under certain conditions, making it easier to refine.

Evaluation of Human Interaction and Usability

Beyond functionality, RP enables designers to assess how users interact with the product. This is crucial for improving user experience (UX), ensuring intuitive design, and identifying any potential issues that could affect usability, comfort, or accessibility.

Conclusion

Rapid prototyping can reduce the time between iterations and allow engineers to discover inventive ways of solving any design engineering problems.

RP can be used at any stage of the product development cycle, but is most effective early in the process so that risks can be mitigated early and designs can evolve more efficiently. Prototyping helps make educational, informed decisions by gathering data from the performance and reaction to the different prototypes.

As specialists in the design, development, and manufacturing of advanced lighting systems particularly within the medical and therapeutic space, we understand the importance of precision and speed in bringing cutting-edge solutions to life. Rapid prototyping enables us to push boundaries in performance and usability while staying agile in a fast-evolving industry.

Ready to bring your vision to light? Contact us today to explore how rapid prototyping can accelerate your product development.

Frequently Asked Questions

What industries benefit most from rapid prototyping?

Rapid prototyping is widely used in industries like automotive, aerospace, consumer electronics, architecture, and especially healthcare, where precision and innovation are crucial. It's particularly helpful for fields requiring customized solutions and fast turnaround.

How does material choice affect the rapid prototyping process?

The choice of material affects the prototype’s strength, flexibility, heat resistance, and finish. For instance, prototyping a functional mechanical part requires a different material than a visual model or concept piece.

What are common challenges in rapid prototyping?

Challenges can include limited material options compared to traditional manufacturing, surface finish limitations, size constraints of the build platform, and the learning curve associated with optimizing CAD files for prototyping tools.

Comments